Glossary of Terms for PowerScore

Resource Innovation Institute is an objective, data-driven non-profit organization whose mission is to measure, verify and celebrate the world's most efficient agricultural ideas.

GENERAL

PowerScore

RII’s specialized resource benchmarking platform

for controlled environment agriculture production facilities.

PowerScore generates KPIs for resource efficiency and productivity of

energy, water, emissions, and waste. The PowerScore platform includes

several components: intake websites and surveys, facility Performance Snapshots, crop-specific Ranked Data Sets,

user profiles, dashboards, and comparative analysis reports.

PowerScore’s free service enables producers to enter self-reported data

through the online PowerScore platform to get an unverified Performance Snapshot

sharing key performance indicators and measuring year-over-year changes

in your facility performance. For CEA markets where there is a

statistically significant crop-specific Ranked Data Set, Performance

Snapshots provide an unverified informative Facility Ranking.

PowerScore Pro

Enhanced

PowerScore dashboard and comparative analysis and reporting platform

that enables benchmarking across portfolios of facilities designed for

producers with multiple facilities (like MSOs), global investors,

efficiency programs, and design & construction partners. RII members

can access PowerScore Pro and receive Competitive Facility Rankings.

PowerScore Comply

PowerScore

intake survey available in markets where resource performance reporting

is required and PowerScore is specified as a qualified benchmarking

platform. Cannabis cultivation license-holders can report required

facility performance details, such as annual production and monthly

resource consumption.

PowerScore Flow

PowerScore intake

survey for users to benchmark facilities using water consumption for

water efficiency and productivity KPIs. This is currently an unpromoted

feature.

DATA

Facility

The site (land and buildings) that comprises a

controlled environment agriculture operation whose resource consumption

and production efficiency is benchmarked in a PowerScore Performance

Snapshot. PowerScore facilities are described in terms of average canopy

area under production.

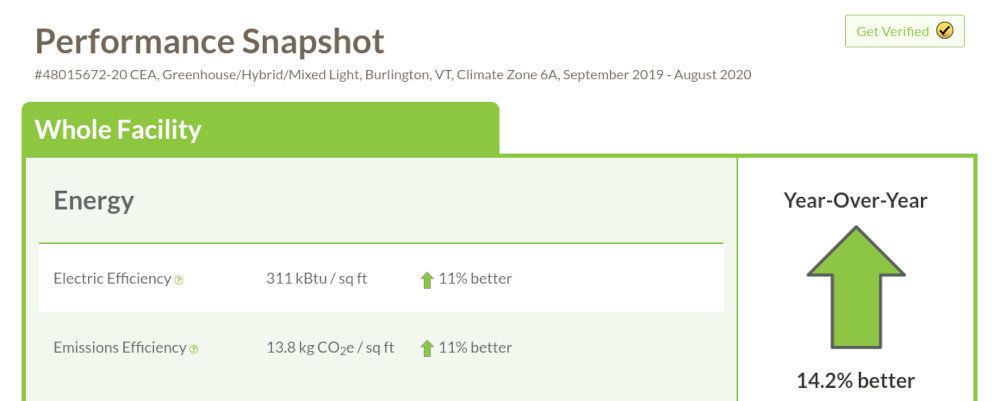

Performance Snapshot

Facility benchmarking summary of one year of production and resource consumption data that can also provide a Year-Over-Year Ranking and/or Facility Rankings.

Performance Snapshots display key performance indicators, rankings,

filters, and facility details from survey responses. Each Snapshot is

unique and is described as a ‘PowerScore record’, and accessed with a

unique URL.

Ranked Data Set

Complete data set of PowerScore records

with archived records removed. Newly submitted records are reviewed for

approval before being added by RII staff into the Ranked Data Set.

Records flagged for data quality issues may be automatically or manually

removed.

Verified PowerScore

Enhanced benchmarking

service available to PowerScore Pro subscribers. System-reported data

submitted for KPIs and rankings are validated by RII and marked as

Verified on the facility’s Performance Snapshot on each KPI that has

been third-party verified with utility bills and system monitoring

reports.

Facility Types:

Facility type is categorized as the room type with the majority of canopy area.

Indoor

Rooms are classified as Indoor if crops are grown under protection without sunlight.

Greenhouse / Mixed Light: Ventilated and Hybrid

Rooms are classified as Greenhouse/Hybrid if crops are grown under protection with access to sunlight as a significant light source, these facilities may include supplemental lighting or may not.

Ventilated greenhouses use traditional greenhouse construction and have permeable building envelopes. This group includes hoop houses.

Sealed, or Hybrid greenhouse facilities are high-performance greenhouse operations in buildings with well-sealed and insulated building envelopes.

Outdoor

Rooms are classified as Outdoor if crops are not grown under protection, with only sunlight.

Reporting

Year-Over-Year Ranking

If enough data is provided, a

Performance Snapshot will include a comparison of prior years’ key

performance indicators and summarize the difference with a

Year-Over-Year Ranking. At least two full years of data are required to

calculate year-over-year changes in KPIs. When comparing one submission (PowerScore A) to another submission (PowerScore B), each KPI is calculated like this:

Facility Ranking (only available for Cannabis)

When enough data is provided in a crop-specific Ranked Data Set, unverified informative Facility Rankings describe a facility’s overall percentile ranking for a given 12 months of data. Facility Rankings use three key performance indicator (KPI) categories: 1) Energy Efficiency & Productivity, 2) Water Efficiency & Productivity, and 3) Waste Efficiency & Productivity. The Facility Ranking weighs the KPI categories: (Energy*50%)+(Water*25%)+(Waste*25%). Each Facility Ranking is then compared to operations of the same cultivation type in the appropriate crop-specific Ranked Data Set. This provides a full range of 0th to 100th percentile rankings, displayed with the PowerScore gauge.

When enough data is provided in a crop-specific Ranked Data Set, unverified informative Facility Rankings describe a facility’s overall percentile ranking for a given 12 months of data. Facility Rankings use three key performance indicator (KPI) categories: 1) Energy Efficiency & Productivity, 2) Water Efficiency & Productivity, and 3) Waste Efficiency & Productivity. The Facility Ranking weighs the KPI categories: (Energy*50%)+(Water*25%)+(Waste*25%). Each Facility Ranking is then compared to operations of the same cultivation type in the appropriate crop-specific Ranked Data Set. This provides a full range of 0th to 100th percentile rankings, displayed with the PowerScore gauge.

Note: If a record does not have scores for all three categories, the category ratios are adjusted. For example, different scores may be calculated with (Energy*100%), or with Energy*67%)+(Water*33%), or with (Water*50%)+(Waste*50%).

Competitive Facility Ranking

Competitive Facility Rankings are enhanced Facility Rankings compared against specific years of Ranked Data Set records to assess KPI trends (year over year changes against the most recent Ranked Data Set).

Producer Resource Efficiency Plan (PREP)

Facility benchmarking summary that gathers PowerScore Performance Snapshot KPI trends, internal operational insights, and competitive recommendations for operators to consider to improve KPI performance and Facility Ranking.

Key Performance Indicator Rankings:

Key Performance Indicator Rankings:

(only available for Cannabis)

KPI rankings are displayed on Performance Benchmark Reports using graduated bar scales displaying percentiles ranked relative to records in the Ranked Data Set that cultivate in the same way (indoor is compared against indoor, etc).

Facility Size Categories for Comparison Rankings

The KPI and overall rankings are based on comparisons to facilities of similar type and square feet of flowering canopy:

- Small Indoor (less than 5,000 sf)

- Medium Indoor (5,000-10,000 sf)

- Large Indoor (more than 10,000 sf)

- Small Greenhouse/Hybrid (less than 5,000 sf)

- Medium Greenhouse/Hybrid (5,000-25,000 sf)

- Large Greenhouse/Hybrid (more than 25,000 sf)

- Small Outdoor (less than 10,000 sf)

- Medium Outdoor (10,000-40,000 sf)

- Large Outdoor (more than 40,000 sf)

Facility Efficiency KPIs

Facility Efficiency KPIs are based on canopy area, area dedicated to growing mature plants. For cannabis, the canopy area used in Facility Efficiency KPIs is flowering canopy only.

Energy Efficiency (Category, Percentile)

This is a category average of the percentile rankings of a record’s available Energy KPIs of the following: Electric Facility, Non-Electric Facility, Electric Production, Non-Electric Production.

Facility Energy Efficiency (kBtu / sq ft)

Total (all fuels) annual energy use per square foot, in units of kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Total (all fuels) energy use per square foot, in units of kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Facility Energy Efficiency is the sum of Electric Facility Energy Efficiency and Non-Electric Facility Energy Efficiency, defined below:

Electric Facility Energy Efficiency (kBtu / sq ft)

Annual electric energy use per square foot, in units of kWh/sq ft or kBtu/sq ft of canopy. A lower value is better; a higher value is worse. Annual electric energy use per square foot, in units of kWh/sq ft or kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Annual electric energy use per square foot, in units of kWh/sq ft or kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Non-Electric Facility Energy Efficiency (kBtu / sq ft)

Total of all annual non-electric energy use per square foot, in units of kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Total of all non-electric energy use per square foot, in units of kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

Facility Energy Emissions Efficiency (lbs CO2e / sq ft)

Total

annual emissions (measured in lbs CO2e) associated with energy use of

all fuels per square foot of canopy. Electricity emissions are

based on the facility’s state profile. In Non-Electric Efficiency the natural gas emissions factor in a state profile as well. A lower value is better; a higher value is worse.

+ ( Total Gallons of Generator Diesel x 10.16 )

+ ( Total Gallons of Generator Gasoline x 8.89 )

+ ( Total Gallons of Fuel Oil x 10.16 )

+ ( Total Gallons of Propane x 5.76 )

+ ( Total Annual Megawatt Hours Nitrogen Oxide Emissions lbs x 298 )

+ ( Total Annual Megawatt Hours Carbon Dioxide Emissions lbs ) )

Total of all emissions use per square foot, in units of lbs CO2e/sq ft of canopy. A lower value is better; a higher value is worse.

Crop Specific Productivity KPIs

Productivity KPIs use the percentage of total canopy area dedicated to that crop to allocate the amount of energy, water, waste or emissions to that crop. Cannabis crops are normalized to dry weight at an estimation of 20% of wet weight or fresh frozen weight.

Crop Specific Energy Productivity (kBtu / lb)

Total all fuels energy consumption (converted to kBtu) per production using a facility’s annual production and whole-facility energy consumption totals. A higher value is better; a lower value is worse.

+ Total Annual Non-Electric kBtu )

Facility Energy Productivity is the sum of Electric Facility Energy Productivity and Non-Electric Facility Energy Productivity, defined below:

Electric Crop Specific Energy Productivity (kBtu / lb)

Total electric energy use (converted to kBtu) per produced pound of dried cannabis flower using a facility’s annual production and whole-facility electricity consumption totals.

A

higher value is better; a lower value is worse.

Non-Electric Crop Specific Energy Productivity (kBtu / lb)

Total non-electric energy consumption (converted to kBtu) per produced pound of dried cannabis flower using a facility’s annual production and whole-facility energy consumption totals. A higher value is better; a lower value is worse.

Crop Specific Energy Emissions Productivity (lbs CO2e / lb)

Total annual emissions associated with energy use of all fuels (converted to lbs CO2e) per production. Total emissions calculated as

above. A lower value is better; a higher value is worse.

Crop Specific Lighting Productivity (Wh / day / lb)

Productivity of electrical energy use from lighting equipment in units of watt hour per day per pound. If multiple crops share a growing space, then those lights’ watt hour multiplied by a crop’s proportion of canopy area. A lower value is better; a higher value is worse.

Lighting Energy Efficiency (Wh / day / sq ft)

Efficiency of

electrical energy use from lighting equipment in units of watt hour per day per square foot of canopy. If multiple crops share a growing space, then those lights’ watt hour multiplied by a crop’s proportion of canopy area. A lower value is better; a higher value is worse.

If Hours Per Day In Operation was not explicitly provided by the grower, then the calculations default to 12 hours per day for flowering areas, and 18 hours per day for all others.

Bonus Points for Third-Party Certified Lighting Equipment:

Using LED lighting products listed on the DesignLight Consortium's Horticultural Qualified Products Library adds up to 5% to Energy Score.

- 5 points total available for DLC-listed equipment

- 1 point minimum for any lighting product on the DLC Hort QPL

- Up to 4 points available based on Photosynthetic Photon Efficacy, PPE) (μmol/J) in the PAR range (400-700nm)

Lighting Power Density KPIs (only available for Cannabis)

Lighting Power Density (LPD) KPIs provided on PowerScore Pro dashboard

reports are: Weighted LPD (all grow areas), LPD Flower, LPD Veg, LPD

Clone & Mother, and HLPDMA. HLPDMA equals all lighting wattage

divided by the sum of the flowering, veg, and mother canopy area.

HVAC Energy Efficiency (kBtu / sq ft) (only available for Cannabis)

Estimated* efficiency of electrical energy use from HVAC equipment in

units of electric kBtu/sq ft of canopy. A lower value is

better; a higher value is worse.

- 392 kBtu / sq ft = 115 kWh / sq ft

for System A: Conventional Air Conditioning with Supplemental Portable Dehumidification Units - 262 kBtu / sq ft = 77 kWh / sq ft

for System B: Conventional Air Conditioning with Enhanced Dehumidification - 355 kBtu / sq ft = 104 kWh / sq ft

for System C: Conventional Air Conditioning with Split Dehumidification Systems - 222 kBtu / sq ft = 65 kWh / sq ft

for System D: Fully Integrated Cooling and Dehumidification System

Based on peer-reviewed analysis of Desert Aire's "HVAC Systems and Grow Room Energy Usage"

Efficiency of electrical energy use from HVAC equipment in units of kBtu/sq ft or efficiency of all-fuels energy use from HVAC systems in units of kBtu/sq ft of canopy. A lower value is better; a higher value is worse.

*For PowerScore records using system-reported KPIs, HVAC Energy Efficiency is not estimated, and describes actual efficiency of all-fuels energy use from HVAC equipment in units of kBtu/sq ft of flowering canopy.

Water Efficiency (Category, Percentile)

This is a category

average of the percentile rankings of all of this record’s available

Water KPIs: Water Facility and Water Productivity Efficiencies.

Facility Water Efficiency (gallons / sq ft)

Efficiency of annual water use in units of gallons/sq ft of canopy. A lower value is better; a higher value is worse.

Crop Specific Water Productivity (gallons / lb)

Efficiency of annual gallons of water use per production. A higher value is better; a lower value is worse.

Waste Efficiency (Category, Percentile)

This is a category

average of the percentile rankings of all of this record’s available

Waste KPIs: Waste Facility and Waste Productivity Efficiencies.

Facility Waste Efficiency (lbs / sq ft)

Efficiency of waste use in units of pounds of total annual waste per sq ft of canopy. A lower value is better; a higher value is worse.

Waste Diverted from Landfill (%)

Percentage of total waste (by weight) that is recycled or composted. A higher percentage is better, a lower percentage is worse.

Waste Productivity (lbs / lb)

Efficiency of annual pounds total waste use per production units. A higher value is better; a lower value is worse.